Tel:86-0750-6228802

Fax:86-0750-6228277

Mobile Phone:+8617718861990

Email:yingtong@yingtongpack.com

Address:Xinsha Industry, Muzhou Town, Xinhui District, Jiangmen, Guangdong Country Region China

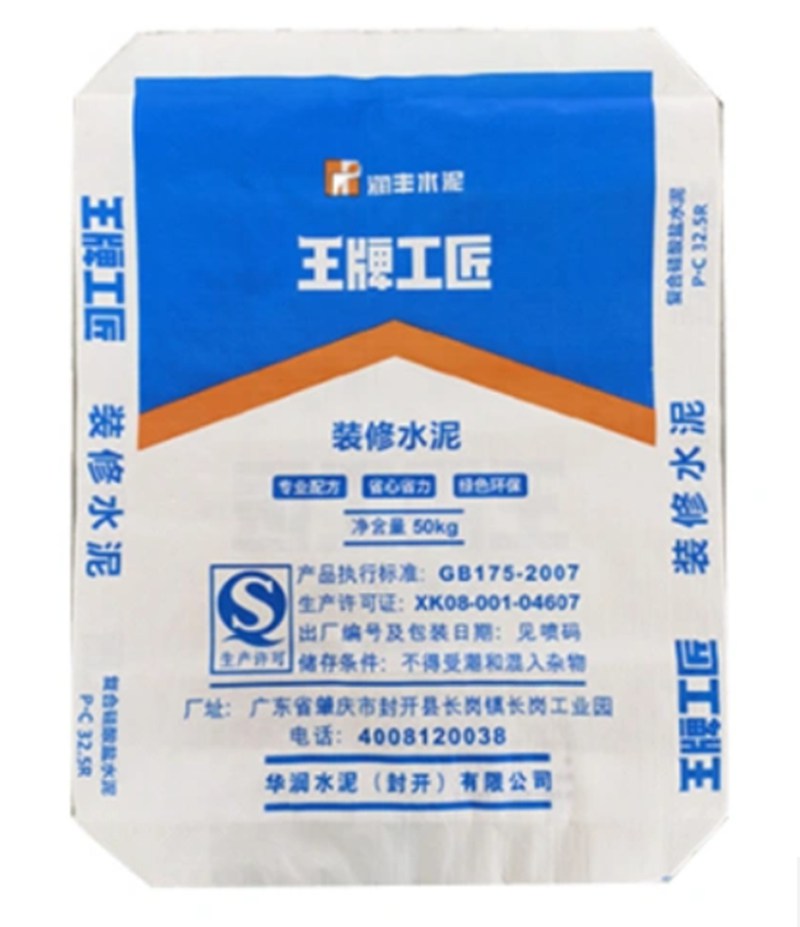

Color Printed Valve Bag is a new type of packaging bag that combines high-precision color printing technology with valve design. Its core structure is composed of a high-strength substrate (such as polypropylene woven cloth, kraft paper composite material, etc.) and a color printing layer, and a one-way valve device is installed on the top or bottom. The product is efficiently filled through automated filling equipment.

Product color: 1-4 colors

Finished size: length 450-910, width 350-600, bottom width 80-180

Pattern customization: plastic woven bags can be customized according to customer requirements

Brand: OEM

Place Of Origin: China

Industry Application: Cement

Making Process: Composite Packaging Bag

Raw Materials: High Pressure Polyethylene Plastic Bag

Bag Variety: Upright Bag

Application: Chemical

Feature: Bio-Degradable

Material: PP

Shape: Square Bottom Bag

Color Printed

High-precision printing: Using gravure printing or flexographic printing technology, 6-8-color high-resolution pattern printing can be achieved, and the color reproduction degree is ≥95%, which meets the needs of brand customization.

Abrasion and scratch resistance: The surface lamination process (such as BOPP film) makes the friction coefficient of the printed layer ≥3.5N, and the pattern integrity exceeds 90% after Taber wear test (CS-10 wheel, 500g load).

Environmental ink: Use environmentally friendly water-based ink that complies with EU REACH standards, VOCs emissions ≤50mg/m³, and meet food-grade contact standards.

Valve

One-way leak-proof design: The valve port is embedded with a silicone sealing ring, and the leakage rate is ≤0.1% under a pressure of 0.2MPa, which is suitable for automated filling lines (filling speed can reach 1200 bags/hour).

Dust and moisture-proof: The valve port structure has passed the IP65 protection level test, can withstand an ambient temperature of -20℃ to 60℃, and effectively blocks dust and moisture.

Strong compatibility: supports a variety of filling heads such as spiral and cannula types, with a valve port diameter range of 8-30mm, suitable for a variety of materials such as powders, particles, and liquids.

Bag

Multi-layer composite structure: The base material uses PP/PE composite film (thickness 80-220μm), with longitudinal tensile strength ≥120N/50mm and transverse tear strength ≥40N, meeting the 50kg load-bearing requirement.

Anti-counterfeiting traceability: optional laser holographic anti-counterfeiting label or QR code printing, supporting one-item-one-code traceability system to improve product safety.

Recyclable design: The base material complies with the ASTM D6400 biodegradability standard, with a degradation rate of more than 60% within 6 months, meeting the requirements of green packaging.

Chemical industry

Application scenario: Packaging of powder materials such as cement, fertilizer, and resin

Solve pain points: The valve port design reduces dust flying (reducing dust by 90%), the color printing layer improves brand recognition, and the composite base material is resistant to corrosion by chemical raw materials (acid and alkali pH value 3-11). Food industry

Application scenarios: packaging of granular materials such as flour, powdered sugar, and pet food

Pain points solved: Food-grade inks and substrates are FDA-certified, valve port seals prevent agglomeration (humidity ≤ 60%RH environment storage period is extended by 30%), and color printing patterns enhance the attractiveness of terminal displays.

Agricultural field

Application scenarios: packaging of seeds, feed, and pesticides

Pain points solved: High-strength bags can withstand transportation extrusion (drop test 1.2m height without damage), color printing layer marks instructions for use and traceability information, and valve port design facilitates mechanized loading and unloading.

Building materials industry

Application scenarios: packaging of mortar, gypsum powder, and putty powder

Pain points solved: Moisture-proof substrates prevent materials from getting hardened by moisture (water absorption ≤ 0.5%), color printing layer marks ratio instructions, and valve ports are compatible with automated mixing station equipment.

Logistics and warehousing

Application scenarios: small packages for cross-border e-commerce, subpackaging of industrial parts

Pain points solved: lightweight design (5kg package weighs only 80g), color printing layer provides multi-language instructions, valve port structure is convenient for robot grabbing and stacking (stacking layers ≥ 10 layers).

Storage environment: avoid direct sunlight (UV aging test shows that the strength retention rate is ≥ 85% after 6 months under 40℃/75%RH conditions), away from sharp objects (puncture resistance ≥ 5N).

Cleaning method: local stains can be wiped with neutral detergent, and organic solvents (such as banana water) are prohibited.

Reusable: The valve port still meets the IP65 standard after 50 opening and closing tests, but single use is recommended to avoid cross contamination.

WhatsApp:

WhatsApp: Phone:

Phone: Contact Now

Contact Now