Tel:86-0750-6228802

Fax:86-0750-6228277

Mobile Phone:+8617718861990

Email:yingtong@yingtongpack.com

Address:Xinsha Industry, Muzhou Town, Xinhui District, Jiangmen, Guangdong Country Region China

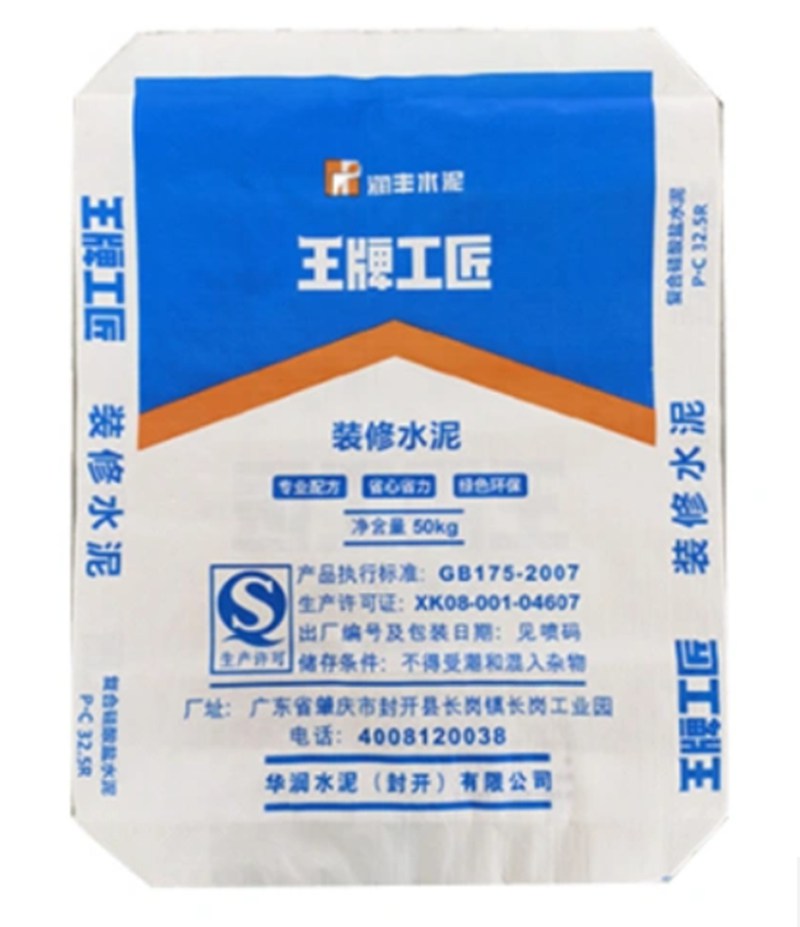

The Block Bottom Valve Cement Packaging Bag is a strong packaging solution for the movement and storage of cement and other building materials. These Cement Packaging Bags are manufactured from high-density polyethylene plastic, making them very strong and durable to guarantee that the contents inside stay safe during transport as well as when being handled.

This square bottom design gives stability and allows the bag to be placed on an end facilitating easy stacking and storage. Its robust plastic woven construction makes it perfect for use in demanding industrial environments where reliability and performance are key.

This PVC woven sack has been designed specifically for you; whether you are handling a construction task in your farm or simply fixing an issue at home, having such a bag will help you get through all your work with peace of mind.

Product color: 1-4 colors

Finished size: length 450-910, width 350-600, bottom width 80-180

Pattern customization: plastic woven bags can be customized according to customer requirements

Brand: OEM

Place Of Origin: China

Industry Application: Cement

Making Process: Composite Packaging Bag

Raw Materials: High Pressure Polyethylene Plastic Bag

Bag Variety: Upright Bag

Application: Chemical

Feature: Bio-Degradable

Material: PP

Shape: Square Bottom Bag

Strong Plastic Woven Construction:

Crafted from high-pressure polyethylene plastic, this Block Bottom Valve Cement Packaging Bag offers exceptional strength and durability, ensuring reliable protection for its contents.

Square Bottom Design:

Featuring a square bottom, this Block Bottom Valve Cement Packaging Bag provides added stability and facilitates easy stacking and storage, enhancing convenience and efficiency.

Ultra-Fine Mouth:

The Block Bottom Valve Cement Packaging Bag can be equipped with an ultra-fine mouth, with each square centimeter capable of accommodating 64 needles, each with a diameter of 0.62mm. This precision engineering ensures secure containment and minimal risk of leakage.

High-Quality valve pockets:

The Block Bottom Valve Cement Packaging Bag is equipped with good quality valve pockets, offering numerous advantages including high strength, impact resistance, prevention of external lines, moisture resistance, corrosion resistance, and excellent slip resistance. These features contribute to the bag's overall reliability and performance.

Sealed Back Cover:

The Block Bottom Valve Cement Packaging Bag features a sealed back cover with fine workmanship, providing double protection against leakage and ensuring the integrity of its contents, even in demanding conditions.

Flexible Filling Options:

The filling mouth of the bag can be customized according to specific needs, allowing for inner or outer filling options. Additionally, the funnel-shaped filling mouth facilitates convenient and efficient material filling, minimizing the risk of leakage and streamlining the filling process.

Construction Industry:

This Block Bottom Valve Cement Packaging Bag is widely used in the construction industry to package and transport cement, sand, aggregates and other construction materials. It has square bottoms design which is made out of a strong plastic woven construction that enables it to hold large amounts of cement for easy transportation at the construction site.

Building Material Supply:

Building material suppliers and distributors use this type of bag when packaging and delivering bulk cement to retailers, wholesalers and construction companies. This Bag is made out of high pressure polyethylene plastic that makes it durable during shipping or handling.

Industrial Applications:

The manufacturing process applies this type of bag particularly where raw materials or additives require cement-like substances. Such bags have a strong plastic woven that prevents leakage or breakage especially during storage and handling periods.

Block Bottom Valve Cement Packaging Bags are typically made of high-pressure polyethylene (PP) plastic, known for its strength, durability, and resistance to tearing and puncturing.

Block Bottom Valve Cement Packaging Bags are ideal for cement packaging due to their strong plastic woven construction, which provides excellent protection against moisture, dust, and external damage during storage and transportation.

Yes, Block Bottom Valve Cement Packaging Bags are designed to withstand heavy loads of cement and other construction materials. The square bottom design and high-pressure polyethylene plastic composition ensure stability and durability under load.

Yes, Block Bottom Valve Cement Packaging Bags are moisture-resistant, making them suitable for storing cement in humid environments or during outdoor storage. The bags' strong plastic woven construction helps prevent moisture ingress and protects the contents from damage.

Yes, Block Bottom Valve Cement Packaging Bag can be customized according to specific requirements, including size, color, printing, and additional features such as handles or liners. Customization options allow for branding and product differentiation.

Block Bottom Valve Cement Packaging Bag can be environmentally friendly depending on their disposal and recycling methods. They are typically reusable and recyclable, reducing waste and promoting sustainability in packaging applications.

Block Bottom Valve Cement Packaging Bag should be stored in a dry, clean, and well-ventilated area away from direct sunlight and sources of heat. Stacking bags on pallets and avoiding prolonged exposure to moisture or sharp objects helps maintain their integrity.

WhatsApp:

WhatsApp: Phone:

Phone: Contact Now

Contact Now